CIVIL ENGINEERING PROJECT REPORT PLASTIC PAVING TILES

|

| Image credit - Bihar Govt. |

CIVIL ENGINEERING PROJECT REPORT ON PLASTIC PAVING TILES

Synopsis of the project

Submitted to

A department of Civil engineering

New Government Polytechnic Patna-13 (Bihar)

By :-

1. NEERAJ KUMAR (6112115170xx)

2. ANKAJ KUMAR (6112115170xx)

3. RAHUL KUMAR (6112115170xx)

4. ADARSH KUMAR (6112115170xx)

Project guide :- Prof. Syed Aftab Ahmed (Lecturer,civil engineering)

Project co-guide :- Prof. Anandi Prasad (Civil engineering)

Department:- Civil engineering

Acknowledgement

ABSTRACT

CONTENTS

2. Objectives 06

3. Literature review 06

4. Material used 07

5. Methodology and procedure 08

6. Advantages and disadvantages 11

7. Result and discussion 12

8. Conclusion 16

9. References 17

1. Figure 01 05

2. Figure 02 08

3. Figure 03 09

4. Figure 04 09

5. Figure 05 10

6. Figure 06 11

7. Figure 07 12

8. Figure 08 15

1. Table 01 13

2. Table 02 13

3. Table 03 14

4. Table 04 14

INTRODUCTION

|

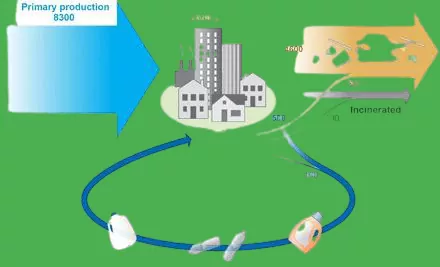

| Figure 1 - Global scenario of fate of plastic (1950 to 2015) |

LDPE - bonded sand is a resource efficient material that can transform waste LDPE into a valuable local resource. LDPE water sachets and other sources can be used to form LDPE-bonded sand. This requires simple processing and produces a durable, relatively light weight material. No water is required in the production process. The following are the salient features of this study.

Ø ⮚ Using recycled LDPE products such as paver blocks and floor tile will not only be economical and environment friendly, but it will also create job opportunities for people.

Ø ⮚ Cost effective recycling solutions are urgently needed to tackle the ever growing problem of waste plastics. The production of LDPE-bonded sand can have major social, public health and environmental benefits.

Ø ⮚ By transforming waste plastics into a valuable resource this simple technology has potential to generate local employment, clean-up the environment, produce new construction materials and significantly reduce the amount of waste LDPE entering the ocean.

OBJECTIVES

Keeping the above said in mind, the following objectives were finalized –

⮚ Finding the optimum ratio of plastic: sand for which the paver block displays the best results in terms of compressive strength, tensile strength, impact resistance, water absorption and heat resistance.

⮚ Analysing the effect of particle size distribution on the properties of paver blocks.

LITERATURE REVIEW

⮚ Plastics are polymers, a very large molecule made up of smaller units called monomers which are joined together in a chain by a process called polymerization. The polymers generally contain carbon and hydrogen with, sometimes other elements such as oxygen, nitrogen ,chlorine or fluorine (UNEP,2009)

⮚ Author Name – Eric Ababio Ohemeng

Title – Utilization of waste low density polyethylene in high strengths plastic pavement blocks production.

Published – 2013

The disposal of waste plastics is causing a great challenge in Ghana and the world as a whole as the usage of plastics is growing day by day and it takes centuries for waste plastics to decompose. Hence, there is the need to adopt effective methods to utilized these plastics. The main objective of this research was to investigate.

⮚ So we construct plastic paving tiles by wasted plastic bag. There are some specific property achieve by plastic paving tiles as compared to normal concrete paving tiles . Such as more durable, lighter than normal concrete paving tiles.

MARERIALS USED

Plastic Bags :-

METHODOLOGY

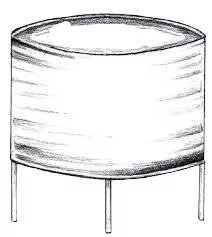

(1) Preparation of a melting barrel :-

|

| Figure 2 Preparation of a melting barrel |

Try to make the burner big enough that you can hold a good amount of liquid plastic but not so tall that it is tricky to mix. If you can sink the legs into the ground it will make the barrel more stable for mixing.

(2) Select the plastic :-

It is important to only select the correct type of plastic. This is because different types of plastic melt and burn at different temperatures and have different physical qualities. Such as LDPE (Low Density Polyethylene is correct type of plastic which melts at moderate temperature .

Water bag , non-woven plastic shopping bags and plastic film are usually made of LDPE. It is important that you do not use other types of plastic – it could be harmful to your health.

|

| Figure 3 Select the plastic |

(3) Cleaning the plastic and shredding it into uniform size :-

(4) Melting of plastic :-

|

| Figure 4 Melting of plastic |

(5) Mix :-

|

| Figure 5 Mix |

(6) Prepare moulding of plastic into tiles :-

Figure 6 Prepare the mould

(7) Allow for set :-

ADVANTAGES & DISADVANTAGES IN PLASTICS PAVING TILES

Advantages :-

i. We can make a variety of building materials that are cheaper than the concrete version.

ii. They set quickly and are very strong. Depending on the mould, you can make floor or paving tiles or even bricks for walls.

iii. They also make good rainwater harvesters: being non-water absorbent, the risk of dew, algae and fungus is almost eliminated, and this ensures clean water.

iv. The cost of paver block is reduced when compared to that of concrete paver block.

v. It can be used in Non-traffic and light traffic road.

Disadvantage :-

i. Concrete block paving can be expensive if specialist blocks such as tumbles or those imitating natural stone setts are chosen.

ii. Inadequate and poorly prepared sub-bases can result in block paving surfaces sinking in high use areas such as those which regularly take the weight of cars.

RESULT & DISCUSSION

Compressive Strength Test :-

Figure 7 Crushed paver block sample of PB2 after CTM testing

It was also observed that the paver block only deformed around the contact area i.e. the area surrounding the actual contact area of load bulged and cracked, whereas the actual area under the load remained more or less unaffected. The only visible difference was the change in colour from black to white over the contact area (Figure 7).

Table 1 Results of compression strength test

Tensile Strength Test :-

Table 2 Results of tensile strength test

Water Absorption Test :-

Table 3 Results of water absorption test

Drop Impact Strength Test :-

| Table 4 Results of Drop Impact Strength Test

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Three samples of each proportion were used for this test. One sample each from PB1, PB2, PB3, PB4 and PB5 batch was dropped from a height of 4 m, 7 m and 10 m to evaluate their resistance against impact (Table 4). It was observed that no visible dents or deformations occurred on any of the sample for a drop height of 4 m. However, when dropped from higher heights, slight dents were formed and in some cases, the sample of paver broke down in two pieces (Figure 8). The samples of PB2 batch displayed the highest impact resistance with no visible deformations on the surface even for a drop height of 10 m.

Figure 8 Breaking of PB4 batch sample when dropped from a height

CONCLUSIONS

v Adding LDPE plastics over heated sand effectively melted the plastics which formed a layer over the sand particles, thereby enabling easy blending of the mix.

v Finally, prepared sample needs to be moulded quickly before it has a chance to cool down. The initial setting takes place at around 20 minutes and the final setting of the paver block takes place at about 4 hours (at standard temperature & pressure and moderate humidity conditions).

v Compaction method and cooling rate are critical to attain optimum properties. Entrapped air bubbles needed to be expelled in order to achieve higher degrees of compaction. These bubbles were noticed during the time of cooling and hence a moderate degree of supervision was needed during the cooling period.

v The sample of sand bonded recycled LDPE paver blocks were evaluated for their compressive strengths. Sample 2 (Plastic: Sand = 1:3) exhibited the highest average compressive strength of 8.14 N/mm2 which is comparable to that of a second class brick or an ordinary clay paver block (used for residential and non-commercial paving purposes).

v The particle size of the sand played a crucial role in determining the final behaviour of the paver blocks. Coarser particles sizes led to lower sample strengths.

v The tensile strengths of the paver blocks were in the range of 1.26 - 3.15 N/mm2. The tensile strength decreased with an increase in the sand content. Sample 2 exhibited the highest tensile strength of 3.15 N/mm2 as determined from the briquettes.

v The water absorption was very low in the range of 2.8 - 11.3% with Sample 1 (Plastic: Sand = 1:2.5) showing the best performance. This indicated that even the worst plastic paver blocks were far superior to the traditional clay paver blocks and bricks.

v The paver blocks were dropped from varying heights of up to 10m. No major deformations were observed on the surface, suggesting that the blocks possess a high impact resistance.

REFERENCES

2. Bassey, G.I., Egbe, J.G., Ewa, D.E., Ettah, E.B., Antigha, R.E. Reprocessing Of Low-Density Polyethylene ( LDPE ) Waste Materials for The Formation Of PVC Ceiling Tiles Using Sawdust As A Reinforcement. J. Archit. Civ. Eng. 2017.3: 9–15 p.

3. Chowdhury, S., Maniar, A.T., Suganya, O. Polyethylene Terephthalate ( PET ) Waste as Building Solution. Int. J. Chem. Environ. Biol. Sci.2013. 1.

4. Geyer, R., Jambeck, J.R., Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017.3:25–29 p.

5. Jain, A., Siddique, S., Gupta, T., Sharma, R.K. Utilization of shredded waste plastic bags to improve impact and abrasion resistance of concrete. Environ. Dev. Sustain. 2018https://doi.org/ https://doi.org/10.1007/s10668-018-0204-1

6. Jassim, A.K. Recycling of Polyethylene Waste to Produce Plastic Cement. Procedia Manuacturing. 2017.8:635–642p. https://doi.org/10.1016/j.promfg.2017.02.081

7. Jnr, A.K., Yunana, D., Kamsouloum, P., Webster, M., Wilson, D.C., Cheeseman, C. Recycling waste plastics in developing countries : Use of low-density polyethylene water sachets to form plastic bonded sand blocks. Waste Manag. 2018.80:112–118p. https://doi.org/10.1016/j.wasman.2018.09.003

0 Comments